Metal belts «Z belt» for baker furnaces

La Bridoire

Metal belts for

La Bridoire Belts have been manufacturing for more than 60 years the famous «Z» belt specially designed to meet the specific requirements of biscuit makers using feed through ovens.

The metal belts, also called metal bands, are long lasting and maintenance is quick and simple. Belts are made of carbon steel and can be made with a width of more than 1.5 meter and lengths up to 300 meters.

Using band Z is the only way to quality.

The global leader in metal belts for baker furnaces. changes management & name.

For a company with ancestral know-how!

The LTL Holding company, located in Crest in the Drôme, headed by THIERRY LECUYER, composed of Tissmétal and M C & I – Métal Concept & Industrie, has been the leader in the metal conveyor belts in France since 100 years.

It has just acquired the “Agrati La Bridoire” division, which is in charge of the production of drawn belts for biscuit ovens. “Agrati La Bridoire”, a French manufacturer of Z-bands since 1919, has become “La Bridoire Belts”.

«La Bridoire belts»

The world’s leading manufacturer of drawn belts for biscuit ovens has been producing the famous “Z” belt for more than 60 years to meet the specific needs of biscuit ovens. The drawn belts, also called “Z” belts, are designed to offer longevity and easy maintenance. French know-how and a unique storytelling!

A HISTORY OF TALENTS !

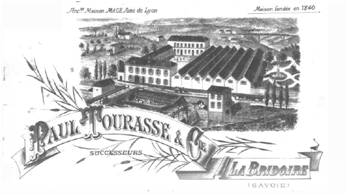

For more than 170 years, the specialist in drawn belts, Agrati La Bridoire manufactures metal belts in La *Bridoire, Savoie. The first company, the “Maison Mage”, was created in Lyon in 1840 to produce metal belts.

At the end of the 19th century, the company moved to La Bridoire in order to use the power of the torrent from Lake Aiguebelette. The new company took the name of its successor: “Paul Tourasse & Cie”.

After the First World War, a new company was created, named “Produits Tréfilés de la Bridoire”.

It resulted from the merger of Etablissements Tourasse with Mr Lévin’s screw factory, which had come to La Bridoire in order to benefit from the advantageous electricity rates offered by the town. Since then, the two factories, Belts and screws, have coexisted in La Bridoire. PTB supplies belts for mine conveyors and wire mesh for the French market.

BIRTH OF THE Z-BELT

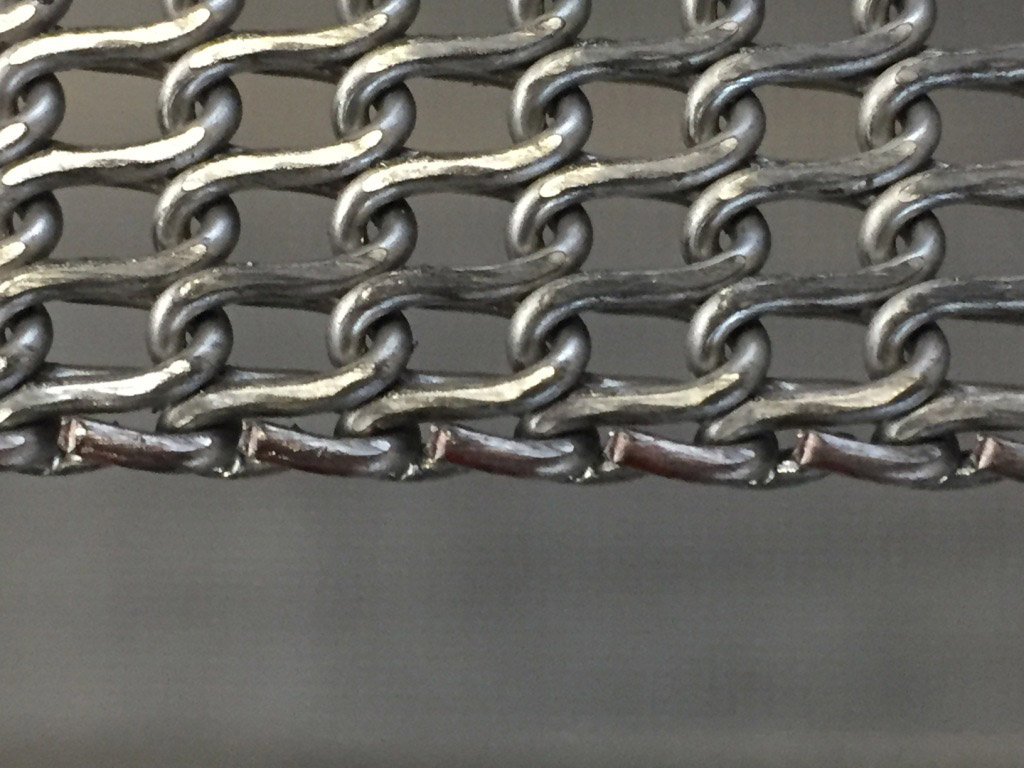

In the 1960s, the famous “Z” belt was created for industrial biscuit factories. It meets the needs for strength, lightness, low thermal inertia and optimised circulation. These characteristics and Agrati La Bridoire’s experience quickly positioned it as the world leader for biscuit ovens.

It is therefore in a logic of industrial deployment specialised in metal mesh that LTL Holding, the FRENCH LEADER, has just completed its range of services with metal strips for ovens, which are delivered to biscuit factories all over the world, directly from the Savoie factory.

RANGE OF METAL BELTS

Z47 is the best in class product used in large installations with high output (speeds up to 30m/ min).

Open space in the mesh allows good air circulation during baking process.

Z47R is a Z47 belt featuring an improved shear resistance for a longer life cycle and intensive use.

It requires a higher heat during baking process.

Z28 has a reduced wire thickness that requires less heat during baking process for improved savings.

High temperature is not recommended. Designed for length of 100 m.

On special demand: Z28R for heavy duty applications. Thanks to the small hole into the mesh, the Z28R belt allows soft dough baking.

Z48 is specially designed for rusks and hard biscuits. Large hole in mesh improve air circulation.

On special demand: Z48S is like the Z48 but with a higher resistance.

TECHNICAL DATA

4 types of belts to meet specific needs of the baking industry :

• Lightweight, reduced size and thickness

• Low heat inertia, good air circulation

• High quality, high strength. Edges are looped for greater flexibility and a better contact with drums – even of small diameters. Edge finish prevents the belt from being damaged by side guides and blades.

• Innovative manufacturing method that provides a perfect alignment of wires for larger open space into the meshes for the same strength. This is key for providing a quick and even baking and helps to keep the belt cleaned.

Loop Edges (thickness +8/10 mm)

• Guarantee longer life time to the edges and to the belt itself being far more resistant to lateral rubbing

• Avoid contact vibrations thus avoiding drop of biscuits in the oven and consequent fire risk

• Protection during cleaning and maintenance

• Greater flexibility and drum contact

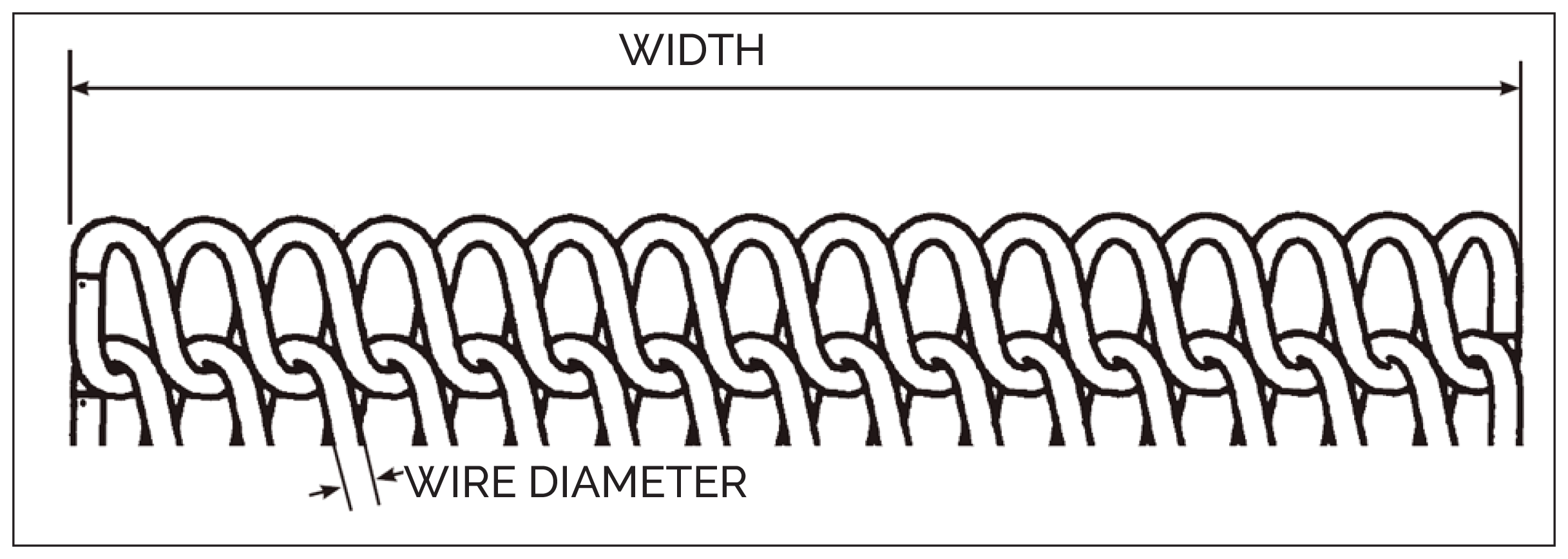

Dimensions

| Z47 | Z47R | Z28 | Z48 | |

|---|---|---|---|---|

| Wire diameter (mm) | 1.2 | 1.5 | 1.0 | 1.3 |

| Pitch (mm) | 8.2 | 8.5 | 6.3 | 8.5 |

| Thickness of the belt (mm) | 2.2 | 2.8 | 1.8 | 2.4 |

| Weight/sq meter (kg) | 7.0 | 11.2 | 6.5 | 7.4 |

| Breaking strength (daN/cm of width) | 240 | 390 | 160 | 220 |

| Max. Width (mm) | 1550 | 1550 | 1500 | 1550 |

| Min drum diameter (mm) | 300 | 300 | 300 | 300 |

Installation: Prior to starting up the conveyor belt, cut the belt to secure the longest possible stroke for the tensioning drum. Tension of the belt must be sufficient to prevent the belt sliding over the driving drum. In any case please ensure that the belt is in the right direction (painted arrow).

Recommendations: It is recommended to change the belt every 3 years when normally used (3 shifts). For more intensive use or very high temperature furnaces expected life can be reduced. Normal lead time for a new belt is from 6 to 10 weeks.

CUSTOMERS

We serve our Customers globally.

CONTACTS

Agrati La Bridoire

Mr. Florent Zanotti

Boite Postale 7

73520 La Bridoire – France

Phone: 00.33.4.76.31.24.26

Mob: 00.33.6.85.83.85.16

Distributors

Italy / Germany

BEARCAT beni industriali s.r.l.

Via De Francesco 23/1

23848 Oggiono LC

Phone – Fax: 0039 0396829514

Mobile: 0039 335271790

Distributors

Asia

Nagatomo Trading inc.

3.6.27.201 Chigasaki Higashi

Tsuzuki Ku – Yokohalas Shi

Kanagawa 224.0033 Japan

Mr Shirani

Phone: 0.45.943.4038

Fax: 0.45.943.4039